TYPE:

NAME:CSD Filling Machine

Carbonated Soft Drink CSD Filling Machine Production Complete Line

Turn-key Project Carbonated Soft Drink Filling Bottling Packing Machines Production Line One Stop Services

Product Description:

This series of Automatic PET Bottle Filling Line are special for carbonated beverage, such as sparking water, aerated water,sprite, coca-cola,gas containing juice etc. The washing, filling and capping will be finished just by this one machine. Convenient to change bottle size by means of advanced bottle conveying technology–bottleneck clamping & bottle suspending technology. It is innovated and designed in the requirement of water filling technics, on the bases of introducing, digesting and absorbing advanced technology abroad. It is reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for beverage producers.

Features:

- Compact structured, good-looking, easy to operate and highly automated.

- Air conveyor is directly linked with feed-in starwheels, making it easier to change bottles without screws and conveyor chains.

- Bottles are transferred in the manner of hanging neck. Bottles can be changed through some replacement, which instead of adjusting the height of machine.

- Rinsing-clamp which special design is strong and endurable, no contact with bottle-mouth, to prevent pollution.

- Highly effective spraying nozzles equipped on the rinsing-clamp can rinse every side of inner bottle and save water.

- Accessories which contact with material are all made of stainless steel, no dead angles and easy to clean up.

- Bottling volume can be controlled by membrane adjusting valves to ensure accurate filling.

- Valve on-off system is driven by hydraulic cylinder, which starts on bottle signals.

- High-speed and highly accurate bottling valves ensure no loss of liquid at high speed.

- Equipped with perfect clean management system to ensure the bottle clean.

- Bottom splint which fixed in the feed-out star wheel goes down in the manner of screw. Bottles can be changed without adjustment of height of conveyor chain.

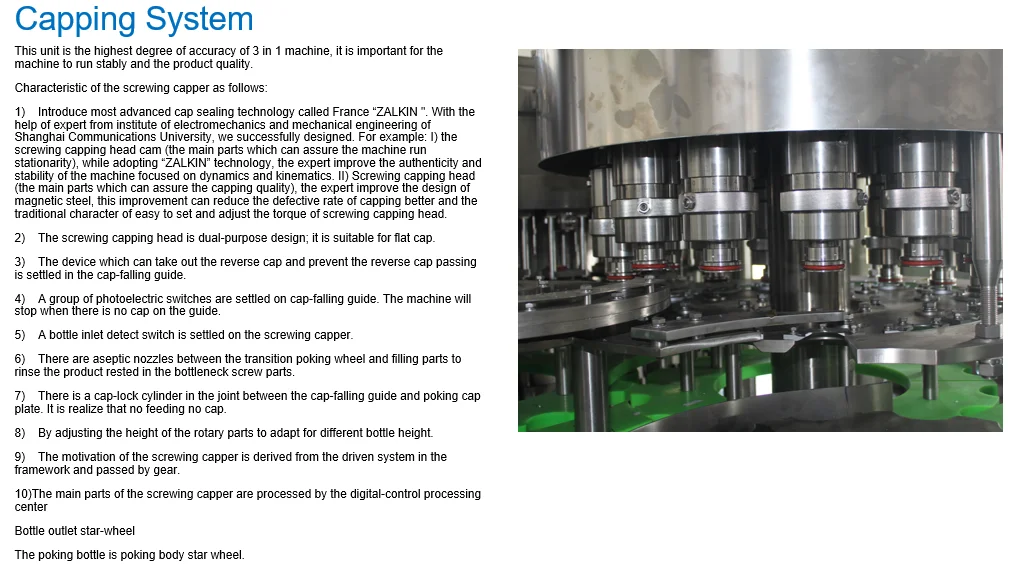

- Capping heads are magnetic constant-torque equipped to ensure capping quality with no damage.

- Highly effective cap sorting and feed in system is protective for feed in and cap absence.

- Equipped with overload system to safeguard machine and operators.

- Touch screen operated.

- Main electronic components (touch screen, PLC and frequency inverter) are imported products.

Main Technical parameters:

| Model | DCGF16126 | DCGF18186 | DCGF24248 | DCGF32328 | DCGF404010 | DCGF505012 | DCGF606015 |

| Heads of washing ,filling , sealing |

16-12-6 | 18-18-6 | 24-24-8 | 32-32-8 | 40-40-10 | 50-50-12 | 60-60-15 |

| Production capacity (bottle/hour) |

2000-3000 | 4000-5000 | 6000-8000 | 10000-12000 | 12000-15000 | 15000-16000 | 18000-20000 |

| Suitable bottle diameter(mm) | φ=50-100 H=170 330-1500ml | ||||||

| Spraying pressure | 2~3 | ||||||

| Motor power | Main motor 1.5kw |

Main motor 2.2kw |

Main motor 3kw |

Main motor 4kw |

Main motor 7.5kw |

Main motor 9.5kw |

Main motor 12kw |

| Power of outer vacuum pump |

0.75 | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 |

| overall dimension (LxWxH) |

2100x 1400x 2500 |

2460x 1720x 2650 |

3100x 2100x 2650 |

3500x 2500x 2650 |

4600x 1800x 2650 |

5200x 4500x 3400 |

6500x 4500x 3400 |

| Weight | 2500 | 3500 | 4200 | 5500 | 6800 | 7600 | 9800 |

Packaging & Shipping:

Our Services:

24Hs after sales service !

Adhere to new products,quality to meet the needs of friends,also have excellent service,welcome all friends to negotiate !

Call Us:

Call Us: